Are you ready to take your project from the design stage to a beautiful, printed magazine? The process of getting your printed version out into the world can be complex and intimidating – but it doesn’t have to be.

There are many processes that go into printing a magazine successfully, so read on for detailed steps on how this is done. Whether it’s understanding Magazine artwork requirements, knowing what kind of paper stock would work best for you, or getting an idea about different options available in print finishing; we’ve got all the information for printing your Magazines here.

Intimidated by color printing languages? Fear not – find out exactly what PMS 877 and CMYK mean, and how they fit together for perfect magazine printing.

So let us guide you through one of the most rewarding experiences throughout your Magazine journey – From design to delivery!

It all starts with an Idea.

Printing a magazine may seem like a daunting task, but fear not my friends! With a little bit of design skill and a lot of patience, you can bring your ideas to life in print.

From the initial concept to the finished product, Magazines are a journey worth taking. And trust me, once you see your work in physical form, you’ll feel like a proud parent watching their child take their first steps.

Just make sure you have plenty of coffee on hand because this process can take a while. But hey, Rome wasn’t built in a day and neither is a killer magazine. So get those creative juices flowing and start designing!

The First Step -Setting up Artwork for Magazine printing

Setting up artwork for magazine printing can be a little daunting for those new to the game. But fear not! It’s as easy as taking Candy off kids!

First things first, make sure your Magazine artwork is set up in the correct format. You don’t want your picture of the Mona Lisa to come out looking like a Picasso, do you?

Next, ensure your artwork is high quality (at least 300dpi, 600dpi if you are using Photoshop) and not pixelated. Nobody likes a blurry print. Finally, double-check everything. Twice. Trust us, you don’t want a typo in the headline of your Magazines

Tips about file formats

Have you ever saved a file only to realize it won’t open on another computer? Frustrating, right? Well, let me share with you some file format tips that are sure to make your life easier.

First things first, always consider your audience when choosing a file format. Will they have the software to open it?

Next, think about the content you’re saving. Is it text-heavy or image-heavy? This will affect which file format works best.

And lastly, don’t forget about compression! Saving in a compressed format can save you storage space and make file transfers a breeze.

Your printer will want a `Print Ready PDF’ for your Magazine – by this, they will want something that is High Resolution, with Bleed (if the Print goes to the edge), and most likely in a scrolling PDF, with the covers separate if they are on different or heavier cover stock.

What files should I submit in ?

Jpgs ? Generally not great.

Canva? Can be Ok but not the best.

Word ? Almost Never – it’s a text program, not great for images or colour.

Adobe ? Now we are talking…Adobe InDesign and Illustrator are the bomb.

Ensuring Colors are correct

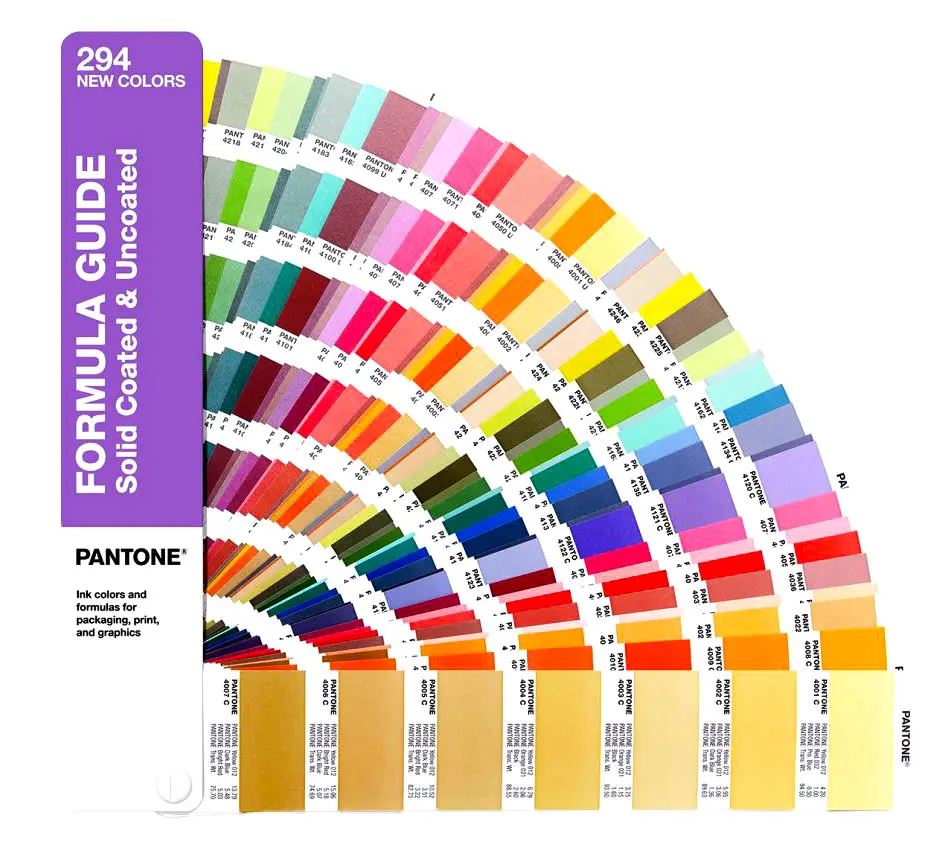

When it comes to ensuring the accuracy of colors, there are a few printing options to keep in mind.

First and foremost, check and double-check your settings to make sure that everyone is on the same page (literally and figuratively).

Print is in CMYK format for Full Colour – not RGB. RGB is screen resolution, and if you are set this way, there will be a colour shift with your printed product

Additionally, be sure to test your colors in different lighting situations to get a better understanding of how they will be perceived by your audience when reading your Magazines.

Remember, if you have a specific Corporate Livery, and need colours matched 100% – Pantone Colours are the only way to achieve this. CMYK is far more popular, but there is a variance factor.

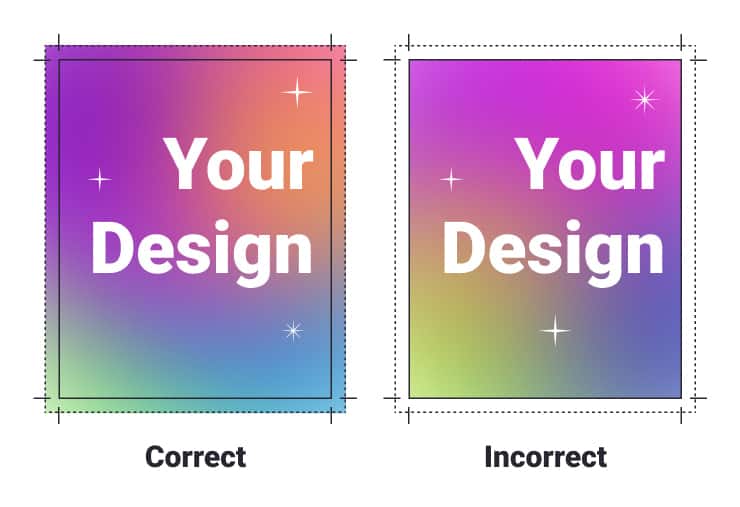

What is Bleed?

If you’re designing for print, then it’s a good idea to be familiar with the concept of bleed.

Bleed is an area of graphical images that extends past the edge of your document, allowing for a more professional look and avoiding white edges on your final product. It adds an extra 3mm to each edge of the page and is essential for printing full-bleed products such as magazines or flyers.

It’s important to note that any objects near the bleed area (photos, logos, text) should be kept away from the edge in order to avoid being cut off during production.

The Printing Process of a Magazine

Ok, you’ve got your Artwork done. You have your Print File ready, in 300dpi Resolution, with Bleed, and as a print-ready PDF. Let’s go to print !

Overview of the different stages involved in magazine printing

Need a Hard Copy Proof?

The first thing to do is to check the quality of your print. We always recommend getting a hard copy proof, so you can physically check images are sharp and colours true.

This proof will be printed on paper stocks that are similar (if not identical) to that which will be used for the final run.

The Magazine Printing Job Begins

Pre-Press

This is a specific department in any Print House and is where the Print file from your Graphic Designer is prepared for use on the Press.

This involves checking that all images are at a high resolution, Formatting to ensure your Magazine looks perfect, and creating a Digital File (for Offset Litho printing) or plates (for Digital).

Magazine Printing begins…

Once Pre-Press has completed their work, the file is now ready to go to print. This can be either Offset Litho (for larger quantities), which will involve creating plates (one per colour) with water-soluble chemicals, or Digital Printing which involves a large Inkjet printer directly printing onto paper.

Finishing & Binding

Once printed, your magazines need finishing. This will include Trimming and Cutting to size then setting up for Binding

The most common binding options for Print Magazines are Saddle Stitching (stapling the spine of a magazine), or Perfect Binding (where the spine is glued).

Saddle Stitched Magazines

Saddle Stitched Booklets are held together using staples in the spine and can be up to 76 pages depending on paper weight. A Saddle Stitched Booklet would be the most cost-effective way to produce a Magazine.

Perfect Bound Magazines (PUR)

Perfect Bound Books use a strong adhesive to bind the cover and inside pages together, rather than staples like Saddle Stitched Magazines. They have a larger page range (up to 448 pages) and tend to look different from stock books.

Perfect Bound books take a little longer to produce as they need to cure (dry) before they can be shipped out.

Shipping & Delivery

Once your Magazines are finished, the next step is to ship them out. Delivery times vary depending on how far away you are from the Print House. If you have a large order, perhaps ask your printer for a `partial’ as they are bound to get you rolling.

Now Go Sell and Distribute your Magazine!

Once your Magazines are off the press and have arrived to you, it is time to get them into the hands of readers. You can do this in a variety of ways, such as:

- Distributing through an app or website

- Selling through retail stores

- Subscription services (digital & physical)

- Promotional campaigns

- Events & trade shows

You may also consider other creative ways to get your Magazine into readers’ hands, such as partnerships with influencers and press outlets or creating promotional bundles with complementary products. All of these options can help boost sales and grow your audience.

No matter which distribution method you choose, make sure that you reach the right audience and properly track the success of your efforts. That way you can measure what works and adjust accordingly.

Good luck with your Magazine Printing venture! With careful planning, creative ideas, and hard work, you’ll have an amazing magazine in no time. Enjoy!