Welcome to our comprehensive guide on GSM in paper! If you’re new to the printing industry or simply interested in understanding how paper quality influences printed materials, you’ve come to the right place. GSM, or grams per square meter, is a crucial aspect of paper that plays a significant role in determining its weight, thickness, and overall quality.

In this guide, we’ll delve into the world of GSM in paper and explore its importance in the printing industry. We’ll explain how GSM is measured, its implications for paper weight and thickness, and the different types of GSM paper available. Additionally, we’ll discuss how GSM influences the perception of paper quality, the manufacturing process of paper, and crucial factors to consider when choosing the right paper weight for your project.

So, whether you’re a business looking to print brochures, flyers, or business cards, or an individual interested in understanding the science behind paper quality, this guide will provide you with valuable insights. Let’s dive in!

Key Takeaways:

- GSM, or grams per square metre, is a crucial aspect of paper that determines its weight and thickness.

- GSM is an essential factor to consider when selecting paper for printing materials.

- Different types of GSM paper are available to suit various printing needs in the industry.

- GSM influences the tactile feel, visual appeal, and environmental implications of printed materials.

- Choosing the right GSM depends on factors such as cost-effectiveness, durability, longevity, and frequency of use.

Understanding GSM in the Context of Paper Quality

When it comes to paper quality, understanding GSM (grams per square meter) is essential. GSM is a measure of the weight and thickness of paper and plays a crucial role in determining the overall quality of printed materials.

GSM measures the weight of paper in grams per square meter, indicating how dense and durable the paper is. Higher GSM values generally indicate thicker and more substantial paper, while lower GSM values indicate thinner and lighter paper.

The GSM of paper significantly impacts its suitability for different printing purposes. For example, higher GSM paper is commonly used for brochures, flyers, and business cards, as it offers a more professional and substantial feel, while lower GSM paper is ideal for lightweight printing needs like letterheads and envelopes.

By understanding GSM and its implications for paper quality, you can make informed decisions about selecting the right paper for your printing projects. The GSM paper guide provides a comprehensive resource for identifying the appropriate GSM range based on your specific requirements.

| GSM Range | Recommended Usage |

|---|---|

| 70 – 100 GSM | Perfect for letterheads, copy paper, envelopes, and proofing |

| 120 – 150 GSM | Ideal for flyers, leaflets, and newsletters |

| 200 – 250 GSM | Best suited for business cards, brochures, and invitations |

| 300 – 350 GSM | Recommended for premium flyers, booklets, and covers |

Choosing the right GSM (or paper thickness)for your printing needs ensures that your materials have the desired look, feel, and durability. Whether you’re printing promotional materials, business stationery, or marketing collateral, understanding GSM is crucial for achieving the best possible results.

Stay tuned for the next section to explore how GSM is measured and its role in determining paper weight and thickness.

GSM in Paper: Measuring Weight and Thickness

In the world of paper manufacturing, GSM plays a crucial role in determining the weight, thickness, density, and overall quality of paper. Understanding paper weight, or grams per square meter, is essential for selecting the right paper for various printing purposes.

What is GSM?

GSM is a measurement used to quantify the weight of paper per unit area. It refers to the weight of a single sheet of paper measuring one square meter. The higher the paper weight value, the heavier and thicker the paper will be.

The Importance of GSM to Paper Weight

GSM measurement is directly related to paper weight. It helps determine the sturdiness and durability of a paper product. For example, business cards and brochures typically use paper with a higher GSM to convey a sense of professionalism and durability. On the other hand, lightweight flyers and posters often utilize paper with lower paper weight for easier distribution.

GSM: A Measure of Density and Quality

In addition to measuring weight and thickness, GSM also provides an indication of paper density and quality. Higher GSM papers are denser and offer better print quality, while lower GSM papers may have a different texture and appearance. The GSM value serves as a standard for comparing the characteristics of different paper types, ensuring consistency in print results.

GSM Paper Types Across the Printing Industry

In the printing industry, various types of paper are available based on GSM (grams per square meter) measurements. Each GSM paper type possesses unique properties and characteristics that make it suitable for specific printing applications. Let’s explore some of the most commonly used GSM paper types and their uses:

- 80 GSM: This lightweight paper is commonly used for everyday printing needs such as documents, letters, and forms. Commonly used as household printer paper

- 100 GSM: A slightly thicker and more durable option, 100 GSM paper is often used for flyers, posters, and brochures.

- 120 GSM: This medium-weight paper is suitable for applications such as booklets, menus, and catalogues.

- 150 GSM: A heavier paper option, 150 GSM is commonly used for high-quality marketing materials like business cards and invitations.

- 200 GSM: This heavyweight paper is ideal for premium marketing collateral, including postcards brochure covers, , greeting cards, and luxury product packaging.

- 250 GSM and above: These ultra-thick paper options are commonly used for magazine covers, business cards with embossing or debossing effects, as well as specialty products like gift cards and certificates.

When selecting GSM paper for different printing projects, it’s crucial to consider the specific requirements and desired outcomes. The choice of GSM paper type can greatly affect the overall look, feel, and durability of the printed materials, ensuring they meet the desired quality standards.

The Significance of GSM for Various Printed Materials

Choosing the right GSM (grams per square meter) for your printed materials is crucial to ensure optimal quality and functionality. Different print materials have specific requirements, and selecting the appropriate GSM can make a significant impact on their effectiveness. Here are some important considerations for choosing the right GSM for business cards, brochures, flyers, posters, booklets, and menus.

Choosing GSM for Business Cards and Brochures

Business cards and brochures serve as essential marketing tools, representing your brand and leaving a lasting impression on potential clients. When selecting GSM for business cards, it’s important to strike the right balance between durability and professionalism. Opt for a higher GSM (around 300-350) to ensure that your business cards are thick and sturdy, conveying a sense of quality to recipients. Similarly, for brochures, a higher GSM (around 120-170) will provide a substantial feel and durability, enhancing the overall presentation.

Appropriate GSM for Flyers and Posters

Flyers and posters are often used to grab attention and convey information effectively. For these materials, a slightly lower GSM (around 80-100) paper stock is recommended. This lower GSM allows for easy distribution and ensures that the flyers and posters are lightweight while still maintaining a good level of durability. The choice of GSM in this range strikes a balance between cost-effectiveness and the visual impact of the printed materials.

GSM Considerations for Booklets and Menus

Booklets and menus require durable paper that can withstand frequent handling and potential spills. A higher GSM (around 150-200) is ideal for booklets, providing a substantial feel and ensuring that the pages remain intact over time. Similarly, menus benefit from a higher GSM (around 120-170) to withstand repeated handling and retain their professional appearance. By opting for a higher GSM, the booklets and menus will exude quality and longevity.

| Print Material | Recommended GSM Range |

|---|---|

| Business Cards | 300-350 |

| Brochures | 120-170 |

| Flyers | 80-100 |

| Posters | 80-100 |

| Booklets | 150-200 |

| Menus | 120-170 |

Choosing the appropriate GSM for your printed materials ensures that they not only look professional but also serve their intended purpose effectively. By considering the specific requirements of each print material, you can make informed decisions and create printed materials that make a lasting impact on your target audience.

GSM Paper Guide: From Thin to Thick

In the printing industry, it is essential to understand the different categories of paper weights. This guide will help you navigate from thin to thick paper options and their applications.

1. Thin Paper

Thin paper, also known as lightweight paper, has lower GSM measurements. It is commonly used for projects that require flexibility and a delicate touch. Examples include:

- Notepads and notebooks

- Letterheads and stationery

- High-volume printing, such as magazines and newspapers

2. Medium Paper

Medium paper falls in the middle range of GSM measurements. It offers a balance between flexibility and durability, making it suitable for various printing needs. Some applications of medium-weight paper include:

- Corporate brochures

- Catalogues

- Flyers and leaflets

3. Thick Paper

Thick paper, also referred to as heavyweight paper, has higher GSM measurements. It offers a sturdier feel and is ideal for projects that require durability and a sense of premium quality. Here are some examples of where thick paper can be used:

- Business cards

- Invitations and greeting cards

- Event posters and banners

By understanding the different categories of GSM paper weights, you can choose the most suitable option for your printing projects. Whether you need thin, medium, or thick paper, selecting the right paper weight will contribute to the overall quality and impact of your printed materials.

How GSM Influences the Perception of Paper Quality

In the world of printing and design, the choice of paper plays a significant role in determining the overall quality of a printed material. One crucial factor that greatly influences this perception is the GSM (Grams per Square Meter) of the paper. GSM refers to the weight and thickness of the paper and has a profound impact on how the paper feels, looks, and even its environmental implications.

The Tactile Feel of Paper Weight Variations

The tactile feel of paper is an essential aspect of the overall user experience. Different paper weight variations offer distinct tactile sensations when touched. Lighter GSM papers, such as those around 60-70 GSM, tend to be thinner and more delicate, while heavier GSM papers, like those above 200 GSM, have a more substantial and sturdy feel. The choice of paper weight can influence the perception of paper quality through the tactile experience it provides.

Visual Appeal and GSM Selection

Visual appeal is another crucial aspect that determines the perceived quality of printed materials. Paper weight selection affects the appearance of the final product, as different paper weight levels can impact ink absorption, color vibrancy, and overall print clarity. Lighter papers may yield a more translucent and lightweight appearance, suitable for designs that require a subtle and elegant touch. On the other hand, heavier papers offer a more solid and robust look, making them ideal for projects that demand durability and a premium feel.

Environmental Implications of Different GSM Levels

When considering the environmental impact of paper, paper weight levels have a significant role to play. Higher GSM papers generally require more raw materials to produce due to their increased weight and thickness. This can have implications for deforestation and carbon emissions. Opting for lower GSM papers, which are lighter and require fewer resources, can contribute to a more sustainable approach to printing and design.

Comparison of GSM Variations and Their Effects

| GSM Range | Tactile Feel | Visual Appearance | Environmental Implications |

|---|---|---|---|

| 60-70 GSM | Thin and delicate | Translucent and lightweight | Less resource-intensive |

| 80-100 GSM | Moderate thickness | Crisp and balanced | Relatively sustainable |

| 120-150 GSM | Substantial and sturdy | Rich and vibrant | Medium environmental impact |

| Above 200 GSM | Thick and robust | Solid and premium | High resource consumption |

GSM and the Manufacturing Process of Paper

In the world of paper production, GSM plays a crucial role in ensuring consistent paper quality. Let’s take a closer look at how GSM is related to the manufacturing process of paper and how it is measured and maintained.

GSM, or grams per square metre, is a unit of measurement that quantifies the weight and thickness of paper. It is calculated by weighing a one-square-meter sheet of paper and determining its mass. This measurement helps determine the density and quality of the paper, which in turn impacts its suitability for different printing purposes.

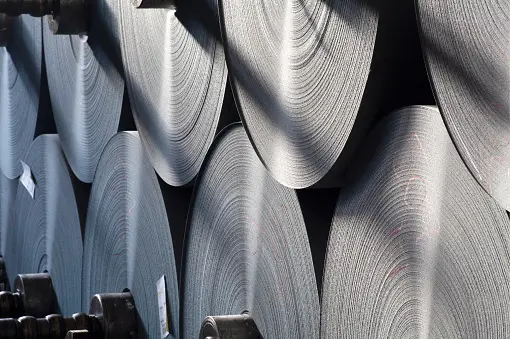

During the paper manufacturing process, various factors come into play to achieve the desired paper weight. These include the selection of raw materials, such as wood pulp or recycled paper, and the use of additives like sizing agents and fillers. The manufacturing process involves pulping, refining, and forming the paper sheet, followed by drying and finishing.

Quality control measures are implemented throughout the manufacturing process to ensure the paper weight is maintained consistently. This includes regular GSM testing to monitor and adjust the paper’s weight and thickness. Additionally, paper mills employ various techniques to ensure uniformity and minimize variations in paper weight, such as refining the pulp and maintaining strict process controls.

By maintaining a consistent paper weight, paper manufacturers can guarantee that the paper they produce meets the required quality standards. This enables printers and end-users to have confidence in the paper’s performance and ensures optimal printing outcomes.

| GSM Manufacturing Process | Steps |

|---|---|

| Pulping | Raw materials such as wood pulp or recycled paper are processed to create pulp. |

| Refining | Pulp is refined to improve its quality and consistency. |

| Forming | The pulp is formed into a continuous paper sheet. |

| Drying | The paper sheet is dried to remove moisture. |

| Finishing | The paper sheet undergoes additional processes such as coating or calendering to achieve the desired characteristics. |

Through the meticulous manufacturing process and stringent quality control measures, paper manufacturers can ensure that the GSM of their products meets the required specifications. This, in turn, contributes to the overall quality and performance of the paper, making it suitable for a wide range of printing applications.

Choosing the Right GSM for Your Project

When it comes to selecting the appropriate GSM for your project, several factors should be taken into consideration. These factors can significantly influence the choice of GSM, ensuring cost-effectiveness, durability, longevity, and frequency of use.

Factors That Influence GSM Choice

Choosing the right GSM involves considering various factors that align with the specific requirements of your project. These factors include:

- Printed Material: Different types of printed materials may require varying levels of GSM to achieve the desired quality and durability.

- Target Audience and Perception: The target audience and their perception of paper quality play a crucial role in determining the appropriate GSM. A higher GSM may be preferred for materials intended to convey a sense of professionalism and luxury.

- Printing Technique: Certain printing techniques may require specific GSM to ensure optimal results. Consult with your printer to determine the suitable GSM for the chosen printing method.

- Budget: Cost-effectiveness is a vital consideration. Choosing a GSM that meets your budgetary constraints while still maintaining the desired quality is essential.

Cost-Effectiveness vs. Durability

When selecting the right GSM, you must assess the balance between cost-effectiveness and durability. A higher paper weight generally implies a thicker and more substantial paper, which can contribute to its durability. However, it is essential to evaluate whether the additional durability is necessary for your specific project, as a higher GSM can also increase the overall cost.

Longevity and Frequency of Use

Consider the longevity and frequency of use when choosing the GSM for your project. If the printed materials will be subjected to frequent handling or environmental factors, opting for a higher GSM can ensure increased durability and longevity. On the other hand, if the materials have a shorter lifespan or will only be used occasionally, a lower GSM may suffice.

Common GSM Paper Sizes for Printing Needs

In the printing industry, it is important to choose the right paper size for your projects. The commonly used GSM paper sizes vary depending on the printing needs and requirements. Here are some of the standard paper dimensions and their applications:

| Paper Size | Dimensions (mm) | Printing Needs |

|---|---|---|

| A0 | 841 x 1189 | Large format prints, such as posters and banners |

| A1 | 594 x 841 | Architectural plans, presentations, and large posters |

| A2 | 420 x 594 | Posters, art prints, and conference materials |

| A3 | 297 x 420 | Brochures, flyers, and reports |

| A4 | 210 x 297 | Business cards, letterheads, and documents |

| A5 | 148 x 210 | Booklets, notepads, and postcards |

| A6 | 105 x 148 | Invitations, RSVP cards, and small flyers |

These are just a few examples of the common GSM paper sizes used in the printing industry. Choosing the appropriate paper size based on your specific printing needs ensures that your printed materials are visually appealing and well-suited for their intended purpose.

GSM: The Backbone of Professional Printing

In the world of professional printing, GSM (Grams per Square Meter) is a crucial factor that determines the quality and performance of printed materials. Professionals pay meticulous attention to GSM because it plays a vital role in delivering exceptional printing results that meet the highest standards.

Why Professionals Pay Attention to GSM

The importance of GSM in professional printing cannot be overstated. By carefully selecting the appropriate GSM for each printing project, professionals can ensure that the final product meets the desired specifications and delivers a lasting impression.

GSM affects various aspects of printed materials, including their weight, thickness, and overall durability. Professionals understand that the right GSM can enhance the tactile feel of printed materials, convey a sense of quality, and make a lasting visual impact on the audience.

Standardizing GSM for Consistency in Printing

To maintain consistency in printing, standardization of paper weight is essential. By following standardized paper weight guidelines, professionals can ensure that every printing job meets the required quality standards and meets customer expectations.

Standardizing paper weight involves selecting predefined GSM ranges for specific purposes, such as business cards, brochures, flyers, posters, booklets, and menus. This helps maintain consistency in the texture, weight, and overall feel of the printed materials across different projects.

MVP Print’s Approach to GSM Selection

At MVP Print, we prioritize GSM selection to deliver outstanding professional printing results. Our approach involves in-depth consultation with our clients to understand their specific requirements and objectives.

We use our expertise and industry knowledge to recommend the most suitable paper weight for each project, taking into consideration factors such as the intended use of the printed materials, desired durability, and desired visual appeal.

By carefully selecting the optimal paper weight, MVP Print ensures that every printed piece captures the essence of our clients’ brand and delivers the highest level of professionalism and quality.

Conclusion

In conclusion, understanding GSM in paper is crucial for achieving optimal printing outcomes. Throughout this comprehensive guide, we have explored the concept of paper weight and its significance in the printing industry. GSM measures the weight, thickness, density, and quality of paper, making it a vital factor in selecting the right paper for various printed materials.

By choosing the appropriate GSM for business cards, brochures, flyers, posters, booklets, and menus, you can ensure that the paper matches the intended purpose and creates the desired impact. Additionally, considering factors such as cost-effectiveness, durability, longevity, and frequency of use helps in making informed decisions while selecting the right GSM.

The tactile feel and visual appeal of different variations play a significant role in shaping the perception of paper quality. Furthermore, standardizing GSM across the printing industry ensures consistency in print results. Whether you’re a professional printer or an individual seeking printing services, understanding paper weight and its implications is essential for achieving high-quality printing outcomes.

By staying informed about paper weight and its role in manufacturing processes, you can confidently select the right GSM paper for your projects. Remember, GSM is not just a number—it’s the backbone of professional printing. So, pay attention to paper weight and make informed decisions for your printing needs.

FAQ

What does GSM in paper mean?

GSM stands for grams per square meter and is a unit of measure for the weight and thickness of paper. It is used to determine the overall quality and density of the paper.

How does GSM measure paper weight and thickness?

GSM measures the weight of paper by determining the weight of one square meter of the paper. The higher the GSM value, the heavier and thicker the paper.

Why is GSM important in the printing industry?

GSM is important in the printing industry because it helps determine the suitability of paper for different printing purposes. It affects the print quality, durability, and overall appearance of the printed materials.

What are the different types of GSM paper?

There are various types of GSM paper available, ranging from lightweight to heavyweight. Each type has different properties and characteristics suitable for specific printing needs.

What GSM should I choose for business cards, brochures, flyers, posters, booklets, and menus?

For business cards and brochures, it is recommended to use a higher GSM paper for a more professional and durable finish. Flyers and posters can be printed on a medium GSM paper, while booklets and menus can use a lighter GSM paper for easier handling.

What are the different categories of paper weights based on GSM?

Paper weights based on GSM can be categorized into thin, medium, and thick paper. Thin paper has a lower GSM value, while thick paper has a higher GSM value.

How does GSM influence the perception of paper quality?

GSM influences the perception of paper quality by affecting the tactile feel and visual appeal of the paper. Higher GSM paper feels more substantial and is perceived as higher quality. Additionally, different paper weight levels can have environmental implications.

How is GSM related to the manufacturing process of paper?

GSM is related to the manufacturing process of paper as it is measured and maintained during production to ensure consistent paper quality. It is a crucial factor in determining the overall density and thickness of the paper.

What factors should I consider when choosing the right GSM for my project?

Factors to consider when choosing the right paper weight include cost-effectiveness, durability requirements, and the longevity and frequency of use for the printed materials.

What are the common GSM paper sizes used in printing?

Common GSM paper sizes include A4, A3, Letter, and Legal. These sizes are widely used for various printing needs and are available in different paper weight options.

Why do professionals pay attention to GSM in professional printing?

Professionals pay attention to paper weight in professional printing because it helps ensure consistent print quality and standardization. GSM selection is an important aspect of maintaining high-quality printing outcomes.